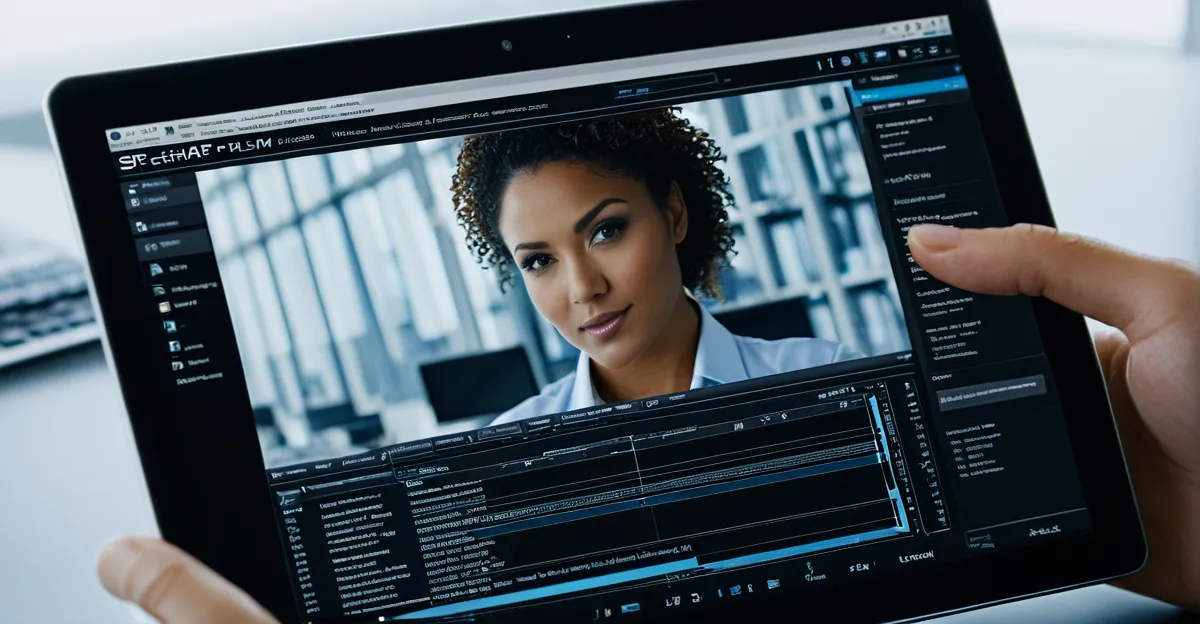

Selecting the right PLM software transforms how businesses manage product lifecycles, connecting data from design to retirement while boosting collaboration across teams. Leveraging smart technologies, these solutions accelerate innovation, reduce errors, and cut time to market—empowering companies to meet rising customer expectations and enhance performance in an increasingly competitive landscape.

Overview of Product Lifecycle Management (PLM) Software and Its Core Benefits

When defining Product Lifecycle Management (PLM) software, the primary purpose is to orchestrate every phase of a product’s existence—from initial idea and design through production, service, and retirement—integrating data, teams, and processes on a single platform for company-wide access. For a comprehensive dive into PLM system choices and their impact on business efficiency, you can view more details on this page: Learn more about it.

Also to see : What Innovations in UK High-Tech Are Revolutionizing Computing Today?

Modern PLM platforms interconnect real-time product data, enabling designers, engineers, manufacturers, and business stakeholders to work collaboratively. Key features often include bill of materials (BOM) management, seamless integration with CAD systems, role-based document control, change management, and advanced analytics. These capabilities establish a “digital thread” that ensures traceability, document control, and efficient data sharing across the value chain rather than siloing information within departments.

The benefits are far-reaching: businesses see enhanced collaboration thanks to unified data and streamlined workflows, which in turn reduce engineering errors and cut costs. Integration with quality management tools and lifecycle documentation supports regulatory compliance and continuous improvement. By leveraging cloud-based, collaborative product development models, organizations respond swiftly to new market demand, optimize production, manage compliance with industry standards, and accelerate time-to-market.

Additional reading : Revamp your life with high-quality notion templates

PLM systems, as foundational tools for digital transformation in manufacturing and other industries, enable teams to innovate quickly, adapt processes, and secure information throughout the product journey—all with reduced manual effort and fewer mistakes.

Essential Features, Selection Criteria, and Industry-Specific Applications of PLM Software

Selecting a PLM solution demands a clear focus on scalability, integration, and deployment. PLM system integration with enterprise resource planning and CRM platforms is fundamental for seamless product data management tools, enabling real-time collaboration and version control in design. Cloud-based lifecycle management now leads, offering rapid scaling and remote access. For highly technical industries, data security measures and role-based permissions are vital, ensuring information is available yet protected.

Industry-specific demands shape PLM strategy. Automotive product lifecycle management hinges on manufacturing process integration and simulation software connectivity, optimizing design-for-assembly and compliance. Aerospace PLM applications benefit from supplier collaboration modules and advanced regulatory compliance management—tracking documentation for stringent standards. In apparel lifecycle optimization, fashion companies rely on cost management solutions and agile product lifecycle software to support fast-changing collections and traceability. Medical device lifecycle tracking highlights the value of digital twin integration and IoT integration in lifecycle management for real-time performance monitoring and regulatory oversight.

Advanced PLM functionalities—such as simulation software connectivity, product portfolio management, and real-time analytics—support continuous improvement, design traceability, and rapid innovation across every industry. Adaptive PLM architectures support project lifecycle management tools, agile deployments, and supplier relationship management, making them indispensable for modern manufacturers.

Leading PLM Software Solutions, Evaluation, and Future Trends

Top product lifecycle platforms are driving digital transformation in manufacturing by combining leading-edge cloud deployment options with robust support and maintenance services. Market leaders such as PTC Windchill, Oracle Cloud PLM, and Arena differentiate themselves through their advanced performance optimization features, scalable architecture, and flexible price models and licensing. Businesses evaluate software vendor selection criteria based on the system’s capability for product lifecycle analytics, real-time product data access, secure cloud-based lifecycle management, and integration with existing ERP solutions.

Comparative software reviews and implementation case studies highlight improved efficiency and regulatory compliance. For instance, manufacturers leveraging user training resources and cross-functional team support experience a significant return on investment through reduced time to market and increased quality assurance. Effective PLM system integration is critical, especially in environments requiring change management features, real-time bill of materials management, and lifecycle documentation tools. Practical onboarding and ongoing support and maintenance services further enhance adoption, minimizing risks during deployment and operation.

Looking to the future, emerging technologies in lifecycle management—led by AI/ML, digital twin integration, and IoT—are enabling agile responses to shifting market demands. Cloud deployment options now support multi-site collaboration, and sustainability initiatives are directly embedded into product portfolio management. This adaptability positions top product lifecycle platforms at the core of user experience improvements and next-generation digital transformation in manufacturing.